FDA can help prevent or mitigate drug shortages by taking actions to address their underlying causes and to enhance product availability. FDA determines how best to address each shortage situation based on its cause and the public health risk associated with the shortage. Some of the steps FDA can take include:

For manufacturing/quality problems, FDA works with the firm to address the issues. Risks posed by manufacturing/quality problems can vary; regulatory discretion may be employed to address shortages to mitigate any significant risk to patients.

FDA can also help meet patient demand by working with other firms to help them ramp up production if they are willing to do so. Often, alternative manufacturers may need new production lines approved or need new raw material sources approved to help increase supply. FDA can and does expedite review of these to help resolve shortages of medically necessary drugs. FDA can’t require firms to increase production.

When a shortage occurs and a firm has inventory that is close to expiry or already expired, if the company has data to support extension of the expiration dating for that inventory, FDA is able to review this and where appropriate, determine that an extended expiration date is supportable to help increase supplies until new production is available.

When U.S. manufacturers are not able to resolve a shortage immediately and the shortage involves a medically necessary drug, FDA may look for an FDA-registered foreign manufacturer that is willing and able to redirect foreign-approved product into the U.S. market to help address the shortage. FDA requests and evaluates relevant information from the manufacturer to determine whether the non-U.S. approved source is suitable to help address the shortage – such as information about the formulation and other attributes of the drug, as well as the quality of the manufacturing site where the drug is made. FDA’s Drug Shortages Staff (DSS) also monitors the shortage situation and determines when product from the non-U.S. approved source is no longer needed.

In rare circumstances, such as a declared public health emergency, natural disaster, or other unforeseen events, multiple firms that manufacture or distribute non-U.S. approved products may reach out to FDA seeking to help address a shortage. In those instances, FDA generally considers those inquiries as they come in, based on DSS’ assessment of the current shortage situation and needs at the time of the inquiry. FDA generally seeks the same type of relevant information from manufacturers (e.g., product formulation, manufacturing capabilities) as in those situations in which DSS initiates a search for potential suppliers, to ensure that any non-U.S. approved source FDA identifies is suitable to help address the shortage.

FDA works to find ways to mitigate drug shortages; however, there are a number of factors that can cause or contribute to drug shortages that are outside of the control of FDA.

Also, FDA issued a long-term strategic plan to outline the agency’s priority actions, as well as actions drug manufacturers and others can take, to prevent drug shortages by promoting and sustaining quality manufacturing.

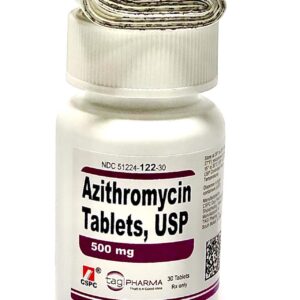

Our Pill Pass® Drug List is only $6.99 or less and Shipping is FREE!

Our Pill Pass® Drug List is only $6.99 or less and Shipping is FREE!