Quality Matters Related to Components of a Drug

FDA continues to identify several issues related to repackagers of bulk drug substances, also called active pharmaceutical ingredients (APIs), and excipients used to compound drugs that have resulted in patient harm.

The agency urges compounders to know your bulk drug substance, or API, and excipient suppliers and know if the supplier is testing the component to ensure it is of appropriate quality to use in drugs. The quality of bulk drug substances and excipients can affect the quality of compounded drugs.

FDA Urges Compounders to:

- know your bulk drug substance and excipient suppliers

- know the quality of the materials you get from your suppliers, including what testing the supplier does to determine the quality of the components you purchase

- meet the conditions regarding bulk drug substances in sections 503A and 503B of the Federal Food, Drug and Cosmetic Act, including:

- API compliance with applicable United States Pharmacopeia (USP) or National Formulary (NF) monograph standars

- sourcing API from FDA-registered facilities

- valid certificates of analysis

- excipient compliance with applicable USP or NF monograph standards

Repackagers should:

- ask compounders how they intend to use the ingredient to help ensure the ingredient is appropriate for use in a drug

- follow all quality standards pertaining to API you repackage

- ensure you have sufficient supply chain transparency to mitigate risks to patients

- clearly identify the original API manufacturer to customers who use them to make the finished drugs

- report quality problems to FDA

- do not have false or misleading labels regarding the identity of the manufacturer of the component you are selling (21 CFR 201.1(h)(2))

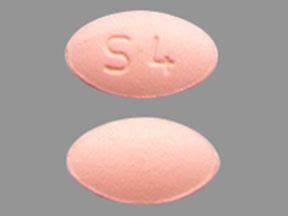

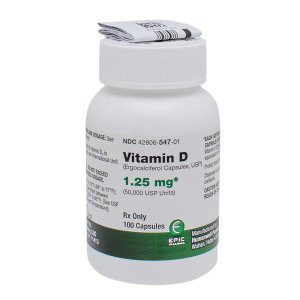

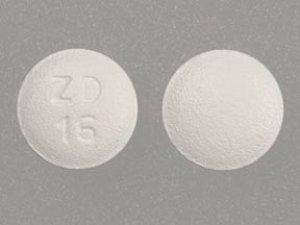

Examples of Quality Issues with Bulk Drug Substances and Excipients

The agency has issued alerts regarding several quality issues:

Additionally, Darmerica recalled bulk API, which shipped API labeled as quinacrine dihydrochloride to compounders nationwide, but subsequent tests identified the API as artemisinin.

FDA Oversight

The agency remains vigilant in our inspections and oversight of the supply chain. We inspect API manufacturers, including repackagers, to help identify and prevent any weaknesses in the drug supply chain. FDA has:

- issued warning letters to API manufacturers, including repackagers, for significant violations of current good manufacturing practice (CGMP) requirements

- placed API repackagers on import alert to help stop their API from entering the U.S. This action helps stop their products from entering the U.S. supply chain.

Resources for Compounders and Excipient Suppliers

- The guidance for industry, Testing of Glycerin, Propylene Glycol, Maltitol Solution, Hydrogenated Starch Hydrolysate, Sorbitol Solution, and Other High-Risk Drug Components for Diethylene Glycol and Ethylene Glycol, provides recommendations that assist compounders, pharmaceutical manufacturers, repackagers and other suppliers of glycerin, propylene glycol, maltitol solution, hydrogenated starch hydrolysate, sorbitol solution and other high-risk drug components, to establish practices that prevent the use of drug components that are contaminated with DEG or EG.

- The guidance for industry, Q7 Good Manufacturing Practice Guidance for Active Pharmaceutical Ingredients contains information on how API, from original manufacturers and API repackagers and relabelers, should identify the original API manufacturer to assure transparency as the API moves through the supply chain. The guidance for industry, Q7 Good Manufacturing Practice Guidance for Active Pharmaceutical Ingredients, Questions and Answers is intended to respond to requests for clarification about the Q7 Guidance.

- There are several United States Pharmacopeia (USP) monographs, including monographs for glycerin, propylene glycol, sorbitol solution, noncrystallizing sorbitol solution, sorbitol sorbitan solution and maltitol solution, that incorporate identity testing provisions for DEG and EG. Information on these and other pharmaceutical excipients at risk for DEG and EG contamination, including appropriate test methods and DEG and EG limits, appears in the applicable USP monographs.

How Compounders Use Bulk Drug Substances and Excipients

Generally, repackagers take bulk API (usually in powder form) or excipients from the container in which the API or excipient was distributed by the original manufacturer and place it into a different container without further manipulation of the API or excipient, for distribution to drug manufacturers, such as compounders. Improper repackaging or lack of supply chain transparency regarding API or excipients can cause serious vulnerabilities in the supply chain and may lead to patient safety issues.

Report a Problem to FDA

We encourage compounders, health care professionals and patients to report adverse events or quality problems associated with compounded drug products, including adverse events that may be linked to API or excipients that may have been contaminated, to FDA’s MedWatch Adverse Event Reporting program:

- Complete and submit the report online at www.fda.gov/MedWatch/report

- Download form or call 1-800-332-1088 to request a reporting form, then complete and return to the address on the pre-addressed form, or submit by fax to 1-800-FDA-0178

-

Content current as of:

10/30/2024